What Are You Looking For?

What Are You Looking For?

Application of Schwahr servo system in the field of industrial automation control

Mar 11, 2023Schwahr servo control system integrates the latest technological achievements in various fields such as electronic technology, computer technology, detection technology, automatic control and mechanical structure, and is a typical electromechanical integration system. Servo systems represented by CNC numerical control systems are mainly used in the field of CNC machine tools such as precision machining, while PLC, as a controlled servo system, has the characteristics of high precision and economy, and has good performance in the field of industrial automation design and transformation with general precision requirements. application prospects.

Composition and principle of servo system

The servo system mainly consists of three parts: servo motor, servo driver, and command mechanism. The servo motor is the actuator, which is used to achieve motion. The servo driver is the power source of the servo motor. The command mechanism sends pulses or gives speed to the servo driver. of. The host computer gives instructions to the servo, such as PLC, industrial computer, etc. The servo driver receives the instructions from the host computer and controls the rotation angle and speed of the motor. The servo motor is the actuator, and its own encoder feeds back the angle and speed of the motor rotation. Give the servo amplifier a closed loop to ensure accuracy.

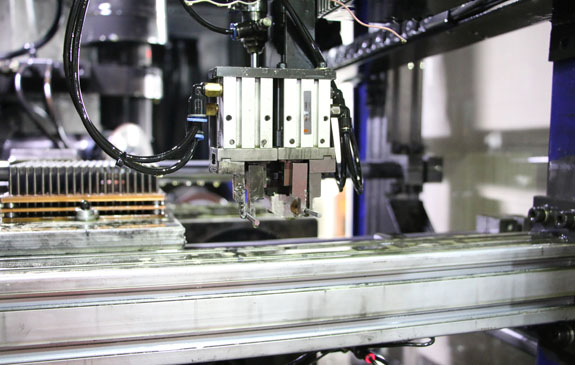

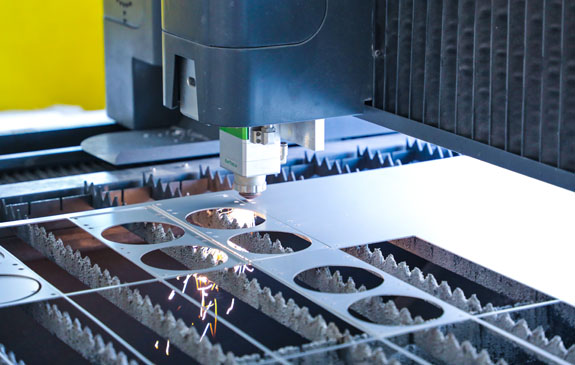

Application of servo in CNC automated machine tools

The role of the servo system in CNC machine tools is often focused on receiving command signals from the control center and driving the movement of each component of the machine tool, so that they can all move under the guidance of scientific instructions, thereby improving the operation quality level of the CNC automation system. Greatly strengthened. In order to achieve this goal of CNC machine tool automation system, it is necessary to improve the operating speed and accuracy of servo control technology, which indicates that a servo drive system with higher control accuracy should be used. The high-precision servo control system can accurately control the selection quality of effective data in the CNC machine tool data collection and collection process, and make each process of CNC automated machine tool work more reasonable, thereby meeting the requirements of production and construction. actual requirements. Only by improving the accuracy of the servo control system can higher-quality processing devices be used in the production process of CNC machine tools. Because today, with the continuous development of science and technology, people's requirements for machining accuracy are becoming higher and higher. Therefore, focusing on the application of servo control technology in CNC automated machine tools can greatly improve the quality and efficiency of work.

Application of servo control technology in automatic system optimization

1) It can improve the accuracy of automated control systems. Automatic control system equipment is very different from ordinary equipment. When automatic control system equipment has corresponding problems, it is not possible to make scientific adjustments and compensation for errors at the first time. Therefore, the accuracy requirements of automatic control equipment are often higher. When servo control technology is applied to the automation system, it can effectively avoid the problem of errors that cannot be adjusted and compensated in time, and can also make the accuracy of each link reach the micron level, thus improving the accuracy of the automation system.

2) Able to do a wide range of speed adjustment work. The speed regulation problem of the automatic control system often determines the quality level of the final work operation. Previous technologies cannot handle this aspect of the work well, but servo control technology, with its many advantages, can fundamentally and continuously adjust the speed of each aspect of the automation system, and its adjustment range is also wider than that of ordinary technologies. The control range is large. Therefore, when servo control technology is applied in automation systems, it is bound to greatly improve the basic performance of the automation system and lay a good foundation for subsequent work. Therefore, applying servo control technology to automation systems can optimize the performance of the automation system in every link, so that various types of automation systems can achieve higher levels of application effects and meet the actual requirements of social production and life.

For example, in order to more comprehensively respond to the urgent need for N95 masks during the epidemic, our company provides overall packaged drive motor(Includes unlimited SCH-T42/T60 Stepper Servo Driver package )solutions for N95 mask production machines from mask machine loading, ear wire, nose bridge, ear wire rotation to folding and welding processes, including Pulse N95 mask machine solution, EtherCAT bus N95 mask machine solution.