What Are You Looking For?

What Are You Looking For?

What is an Infrared Temperature Sensor

Sep 19, 2019Infrared temperature Sensor are revolutionizing the way temperature measurements are conducted across various industries.

Infrared temperature sensor ability to accurately measure temperature from a distance, without any physical contact, makes them suitable for a wide range of applications.

Infrared temperature sensor With non-contact measurement capability and advanced features, these transmitters offer accuracy, efficiency, and convenience unlike any other temperature measuring devices. This article will delve into the multifaceted applications of infrared temperature transmitters and highlight their significance in ensuring precise temperature readings.

Applicantion of Infrared temperature Sensor

Infrared temperature transmitters have found extensive use inIndustrial,Automotive,HVAC ect.

•Monitoring Industrial Processes

One of the primary applications of infrared temperature transmitters is in monitoring industrial processes. In industries such as manufacturing, pharmaceuticals, and food processing, temperature control is critical for ensuring product quality and preventing equipment failure. Infrared temperature transmitters provide real-time temperature readings of machinery, enabling operators to detect any anomalies promptly. This not only enhances precision in manufacturing but also minimizes the risk of costly downtime due to equipment failure.

Infrared temperature transmitters effectively measure the temperature of production equipment, allowing for enhanced process control and the prevention of equipment failures. By providing real-time temperature data, these transmitters enable quick adjustments in parameters, thereby minimizing downtime and optimizing production efficiency.

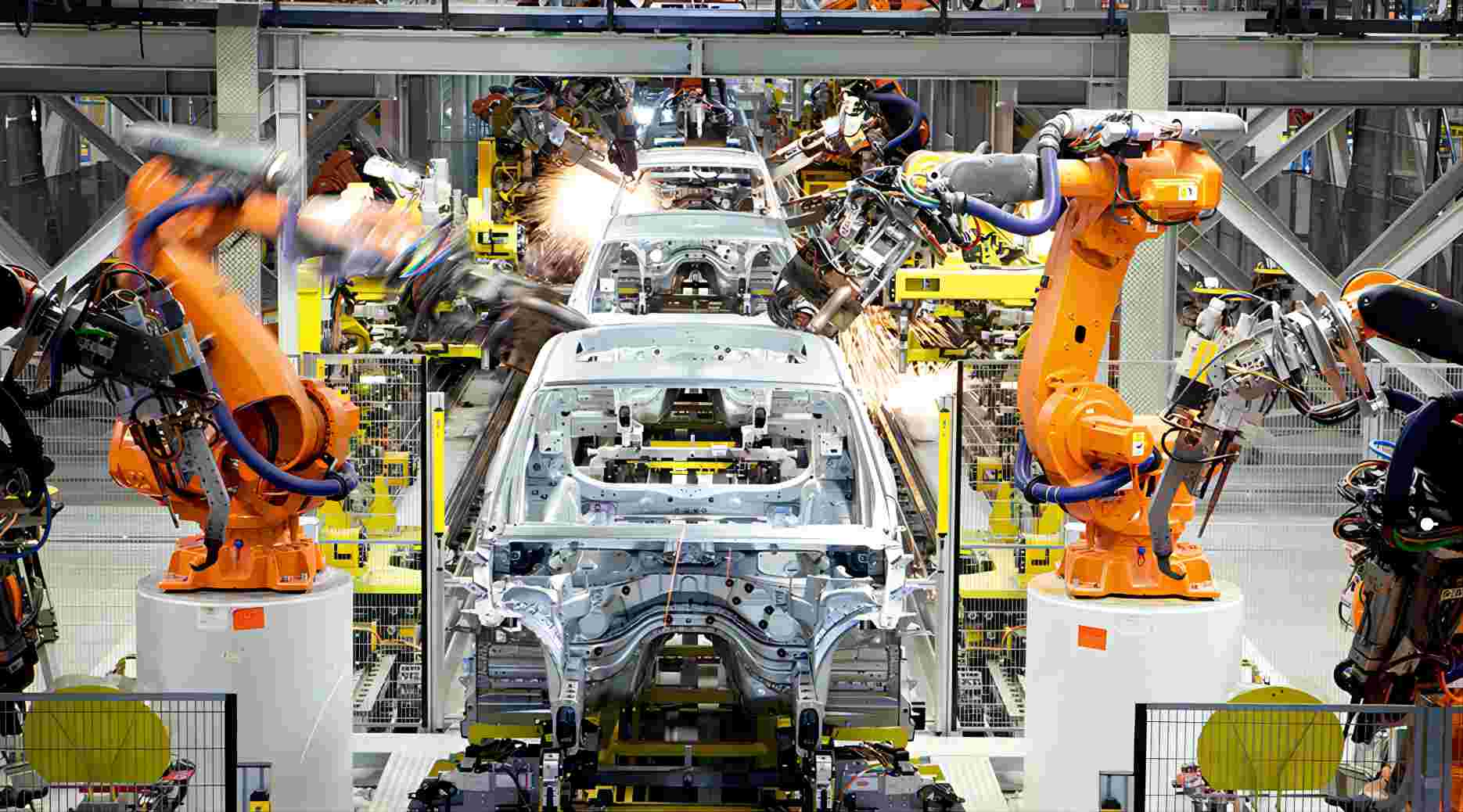

Automotive Application

Automotive manufacturing involves numerous processes where temperature control is crucial. Infrared temperature transmitters enable precise temperature measurements during welding, surface treatment, and curing processes. By monitoring the temperature of components and ensuring adherence to desired temperature profiles, these transmitters enhance product quality and longevity while minimizing rejects and rework.

•Ensuring Food Safety

Food processing facilities rely on accurate temperature control to ensure food safety and prevent spoilage. Infrared temperature transmitters are extensively used in these facilities to monitor temperatures during various stages of production, including cooking, cooling, and storage. By precisely measuring the temperature of perishable food items, operators can ensure compliance with food safety regulations and prevent the growth of harmful bacteria. This application is vital in maintaining the quality and integrity of food products, safeguarding consumer health.

Enhancing Safety and Preventing Fires

Infrared temperature transmitters play a crucial role in safety applications, particularly in preventing fires. By continuously monitoring the temperature of electrical components, transformers, and circuit breakers, these transmitters can detect overheating, a common precursor to electrical fires. Early detection allows for prompt action, such as shutting down the equipment or addressing the underlying issue, thus preventing potential disasters. This application is vital in data centers, power distribution facilities, and commercial buildings where fire safety is of paramount importance.

Benefits of Infrared Temperature Transmitters:

The applications of infrared temperature transmitters bring forth various benefits that cater to different industries. Some common advantages include:

1. Non-contact measurement: By eliminating the need for physical contact, infrared temperature transmitters minimize the risk of contamination and damage to sensitive equipment.

2. Greater accuracy: These transmitters offer precise temperature measurements, ensuring reliable data for process control, maintenance, and troubleshooting.

3. Time and cost savings: Infrared temperature transmitters provide instantaneous temperature readings, reducing the time required for manual measurements. This increases productivity while saving costs associated with labor.

Conclusion

Infrared temperature Sensor have indeed revolutionized temperature measurement techniques in various industries. Their non-contact measurement capability, accuracy, efficiency, and convenience make them indispensable tools for ensuring proper temperature control, preventing equipment failures, and optimizing processes. From industrial facilities to automotive plants, medical facilities to building management systems, these transmitters continue to prove their worth in diverse applications. As technology advances, we can expect further enhancements and integration of infrared temperature transmitters, continuing to shape the future of temperature monitoring.